In the current fast-paced production environment, the requirement for more rapid turnaround times and effective manufacturing processes has reached an all-time essential level. Rapid injection-molding techniques has surfaced as a robust approach, streamlining the way products are developed and launched.

This cutting-edge approach not only speed up the production of plastic parts but also improves the adaptability and cost efficiency of production activities.

By leveraging cutting-edge technologies and practices, rapid injection molding permits companies to lower lead times dramatically while maintaining high precision and quality in their outputs. This article delves into the fundamentals of rapid injection molding, exploring its benefits, uses, and its potential to change the process of developing products. Whether you're a veteran manufacturer or just starting out, comprehending these cutting-edge techniques can be the key to gaining new prospects in effective product manufacturing.

Grasping Rapid Injection Molding

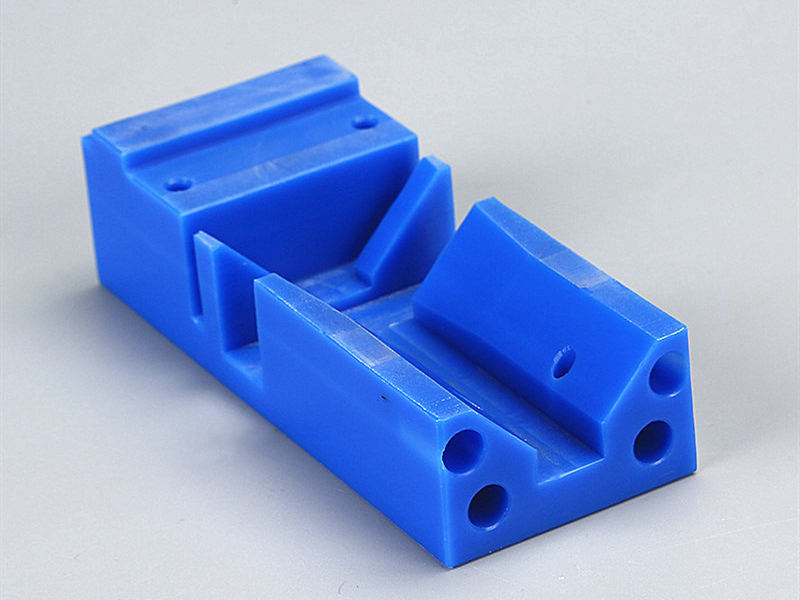

Rapid injection molding is an innovative manufacturing process that enables for the rapid production of plastic parts using injection molding techniques. It merges speed and efficiency, making it an optimal solution for creating prototypes and low to medium volume production runs. By employing advanced materials and refined processes, manufacturers can produce premium components in a limited amount of the time compared to traditional molding methods.

The essence of rapid injection molding lies in its potential to decrease lead times considerably. This is accomplished through the use of rapid tooling, which entails the creation of molds using materials that can be produced swiftly and more affordably. These molds typically have brief design and production cycles, facilitating faster turnaround times for both prototyping and production. This adaptability makes rapid injection molding particularly inviting to businesses looking to cut down their product development timelines.

Moreover, rapid injection molding is ecologically friendly, as it limits waste and recycles materials efficiently. The process allows for greater design flexibility, allowing engineers to make iterative changes quickly based on feedback during the development phase. This approach not only improves productivity but also ensures that the final products meet the specific specifications required for market success.

Benefits of Rapid Injection Molding

Rapid injection provides notable quickness advantages, permitting manufacturers to create prototypes and end-use parts considerably rapidly than standard techniques. This quick delivery is crucial for companies endeavoring to evaluate designs and launch products to market quickly. By utilizing innovative technologies and efficient processes, businesses can improve on their designs significantly effectively and react to market demands with nimbleness.

Cost efficiency is a further key benefit of accelerated injection. Production runs can be started with lower upfront costs compared to conventional molding, especially for small to moderate volume projects. The capability to promptly manufacture molds lowers the duration and work costs associated with prolonged manufacturing processes. As a outcome, businesses can achieve a positive return on investment, making rapid molding an appealing option for diverse applications.

Additionally, fast-track molding ensures superior criteria in the production of parts. The contemporary materials and processes used in this method guarantee that final products exhibit excellent surface finishes and narrow tolerances. This uniformity in quality is crucial for fields such as vehicle manufacturing and medical, where precision and reliability are paramount. As a result, companies can trust that their products will satisfy or exceed customer expectations, boosting brand image and competitiveness in the market.

Applications and Sectors That Utilize Accelerated Injection Moulding

Rapid injection molding is widely used throughout various sectors, enhancing the efficiency of product creation. In the automotive industry, producers employ this method to produce prototype components and complex components rapidly, allowing for faster design iterations and reduced time to market. The capability to make modifications swiftly means that groups can react to design challenges or market demands without the lengthy lead times associated with conventional molding methods.

The consumer electronics industry also benefits significantly from accelerated injection moulding. With the continuous advancement of technology, businesses need to deliver new solutions to the marketplace at an unprecedented pace. Rapid injection moulding allows the production of high-quality enclosures, buttons, and connectors in a short timeframe, allowing rapid turnaround and customization options that satisfy particular consumer needs. This agility is critical for remaining competitive in a rapidly changing market.

In addition, the medical sector leverages accelerated injection moulding for making medical devices and components, such as casings and connectors, with strict regulatory requirements. This method allows producers to create small runs of specialized parts efficiently, guaranteeing that they can satisfy both functional and compliance requirements without the costs associated with massive production. The accuracy offered by rapid injection molding is crucial for guaranteeing the reliability and security of medical products.